The Cornmill: Difference between revisions

PhilRadford (talk | contribs) No edit summary |

PhilRadford (talk | contribs) |

||

| (94 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

The | |||

[[File:The Cornmill 3 Storey Block.jpg|thumb|The Oldest surviving part of The Cornmill was rebuilt in the early 1800's]] | |||

==INTRODUCTION== | |||

The buildings known today as The Cornmill are the last surviving parts of Luddenden's two historic Cornmills.<br><br> | |||

The Luddenden Cornmills were owned on and off by The Murgatroyd family since the first recorded mill in 1274. There is a lot of published information about the early history of the mills (including [https://familymurgatroyd.com/mill.htm Luddenden Mills]). So this article will concentrate on the post-Murgatroyd days, that is from 1854 onwards. But here's a brief early history for you: | |||

=A BRIEF HISTORY OF THE WARLEY SOKE MILL= | |||

The Mill gets it's first mention in 1274 in The Wakefield Manorial Rolls. | |||

The Cornmill was a Soke Mill and was owned and run by the Lord of the Manor or one of his appointees. All the inhabitants of the Borough had to grind their cereals at their Soke Mill and pay a tax, known as Mulcture, to the Lord of the Manor for this privilege.<br> | |||

''Midgley's Soke Mill was on the north bank of the Calder at Brierley bridge by the side of the weir.''<br> | |||

''And the one for Sowerby was on the Calder's south bank opposite Holmes Park at Luddendenfoot.''<br> | |||

The site of the original Warley Soke Mill was a few hundred yards further down the river from today's Mill, somewhere below Lane House and Kershaw House.<br> | |||

It's position is shown on Christopher Saxton's map of 1599 (a copy of which is held by West Yorkshire Archive Service at Halifax Library), but by 1599 the 'new' Mill had been built. <br> | |||

The 'new' mill (the Quenes Milne on Saxton's Map, later to be known as Upper Mill) is clearly marked and was on the site now occupied by High Street Court.<br> | |||

Luddenden at this time was a collection of twelve Houses, the church and the Cornmill.<br> | |||

By 1633 New Mill was getting a bit tired and shabby and in need of an upgrade. The state of the mill was causing a lot of complaints from the locals, as were the state of the access roads to the mills!<br> | |||

So Henry and Jane Murgatroyd had to put their hands in their pockets and pay for some improvements! Their interventions were recorded on this stone lintel which bears their initials and the date of the renovation. This lintel is on display above the mill Stone at the junction of Halifax Lane and High Street in Luddenden.<br> [[File:Cornmill Inscription.jpg|thumb|centre| Inscription on a Stone Lintel from the mill refurbishment in 1633]]<br> | |||

We get the first mention of Lower Mill in a document from 1738 (West Yorkshire Archive Service: Document Ref Misc 78) with a reference to the cottages at the south end of Lower Mill: | |||

''‘wherein oates have and now are dryed and made ready to grind…. Now converted into two dwelling houses’''<br> | |||

please note that only Oats are mentioned, not wheat!<br><br> | |||

The cottages were demolished in the 1860's when the Eastwood family built another 3 storey building of a similar size to the surviving Cornmill building but perpendicular to it. This was situated on the land now occupied by the house know as Jack's Cottage on Bluebell Walk.<br> | |||

This document also mentions that there are: | |||

'''three water Corn Mills under one roof called Warley Mills'.'' | |||

Where the third water wheel was situated is unknown.<br> | |||

[[File:The two storey part of the Mill was built around 1860. .jpg|thumb|right| The Two Storey section built around 1860. The steps to nowhere originally gave access to the buildings here.]]The surviving Cornmill buildings are again rebuilds of older buildings, the current buildings are thought to be from the early 1800's for the three storey section with the two storey section next to the 'steps to nowhere' being built around 1860-70. The steps originally gave access to the mill and had a twin on the opposite side of the road to allow easy access between the two mills.<br> | |||

As I mentioned above, the mills had a total of three water wheels in operation for many years, but as wheel technology improved, two large waterwheels with metal spokes were installed to replace the smaller and heavier wooden wheels. | |||

In the 1840's Lower Mill was converted to Steam power to allow all the water to be used by one gigantic wheel at Upper Mill. | |||

Upper Mill was sold in the 1850's to the Thompson family who continued to mill grain here until the 1890's. Their milling interests then focussed on their other mill at Denholme Mill on Burnley Road and new tenants were sought for the buildings here in the village.<br> | |||

Lower Mill was also sold in the 1850's.The Eastwood family, who already owned mills in the valley converted it into a Woollen Mill. The Eastwood's were bankrupted shortly afterwards and the building changed hands again, being bought by the Thompson family. They rented it out as a woollen Mill and later (1910-20's) it became a garment sewing shop, run by Dickinson Brothers of Hebden Bridge. Finally it became part of Lindley's Nut & Bolt Factory.<br> | |||

Lindley's started their business in Upper Mill in the late 1890's and gradually expanded across the road to Lower Mill and finally onto the plot of land by the river which was known as The Holme.<br> | |||

The site became derelict when Lindley's shut. In the 1990's, the site was transformed into the housing estate, Blue Bell Walk.<br> | |||

The remaining part of the original Lower Mill was converted into eight residential flats.<br> | |||

Upper Mill was demolished in the 1970's and the houses of High Street Court were built here in the 1990's. | |||

= | ===Water Power in Luddenden Dean=== | ||

Grinding Corn was the earliest record for the use of water power in the Luddenden Valley, but there were many uses for this valuable resource. The valley had at least eleven water mills with a | Grinding Corn was the earliest record for the use of water power in the Luddenden Valley, but there were many uses for this valuable resource. The valley had at least eleven water mills with a | ||

[[ | [[INDUSTRY#Water Power in Luddenden Dean| range of uses.]] | ||

===Wheat, Oats and Barley but no Corn=== | ===Wheat, Oats and Barley but no Corn=== | ||

| Line 31: | Line 73: | ||

===Barley Malting=== | ===Barley Malting=== | ||

Barley malting was another important job often associated with Cornmills. Malted barley was used to produce beer. | Barley malting was another important job often associated with Cornmills and here in the village, there was a large malting shed on the site of Upper Mill.<br> | ||

In the malting process, the grains are repeatedly soaked and dried to force the grain to sprout. As the grain germinates, it turns stored starch into sugar to fuel the plant's growth. The maltster needs the grain to produce lots of sugar, yeast | Malted barley was used to produce beer. | ||

In the malting process, the grains are repeatedly soaked and dried to force the grain to sprout. As the grain germinates, it turns stored starch into sugar to fuel the plant's growth. The maltster needs the grain to produce lots of sugar, yeast can then convert this into alcohol in the brewing process. | |||

To germinate the grains they are dried between soakings in long heated drying sheds, the grain is spread thinly on the floor and these are raked to turn the grains over and to keep the moisture at an optimum level. | To germinate the grains they are dried between soakings in long heated drying sheds, the grain is spread thinly on the floor and these are raked to turn the grains over and to keep the moisture at an optimum level. | ||

Once at the correct sugar level, the grains are dried at a higher temperature so that the sprout of the grain dries and falls off. | Once at the correct sugar level, the grains are malted (dried at a higher temperature) so that the sprout of the grain dries and falls off. | ||

The malted grain can be heated to different temperatures to give a range of malt colours for different styles of beer. | The malted grain can be heated to different temperatures to give a range of malt colours for different styles of beer. | ||

Today this is done in ovens with a high degree of temperature control (and we have developed a fascination | Today this is done in ovens with a high degree of temperature control (and we have developed a fascination for very pale beers!!). | ||

Originally, it would have been done with coal fires and a low degree of control and the resulting malt always ended up on the dark side so Beers were darker, porters and stouts being the beer of choice. IPA's were only introduced as the malting ovens became more sophisticated. | Originally, it would have been done with coal fires and a low degree of control and the resulting malt always ended up on the dark side so Beers were darker, porters and stouts being the beer of choice. IPA's were only introduced as the malting ovens became more sophisticated. | ||

| Line 45: | Line 88: | ||

Most of the local pubs would have brewed their own beer (micro breweries were the norm, the successful ones expanding to become the big names that we know today). We know that both the Lord Nelson and The Murgatroyd Arms had brewhouses. | Most of the local pubs would have brewed their own beer (micro breweries were the norm, the successful ones expanding to become the big names that we know today). We know that both the Lord Nelson and The Murgatroyd Arms had brewhouses. | ||

Having a supply of malted barley just down the road would have been useful, but the second most important ingredient for a good beer the right quality of water. | Having a supply of malted barley just down the road would have been useful, but the second most important ingredient for a good beer is the right quality of water. | ||

So if you wanted to start a pub, you must build it where there is some good spring water!! | So if you wanted to start a pub, you must build it where there is some good spring water!! | ||

| Line 57: | Line 100: | ||

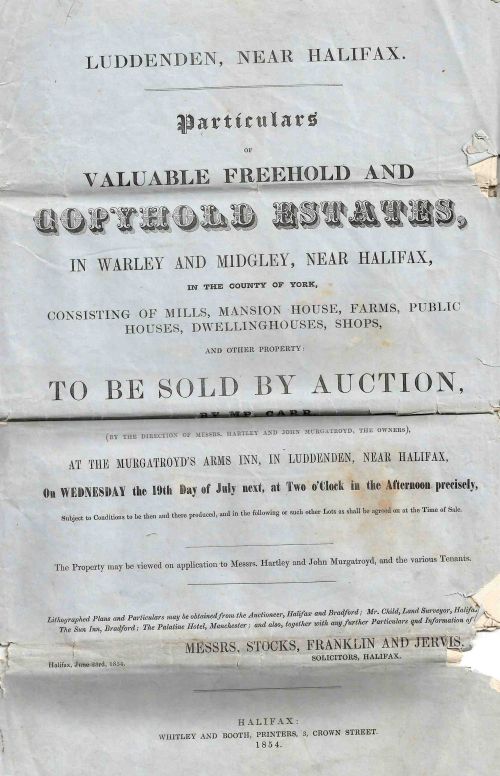

The last Murgatroyds to run the mills were brothers Hartley (1797-1865) and John (1799-1873). This branch of the Murgatroyds had run the Cornmills for over two centuries. | The last Murgatroyds to run the mills were brothers Hartley (1797-1865) and John (1799-1873). This branch of the Murgatroyds had run the Cornmills for over two centuries. | ||

The brother's seem to have got into some financial difficulties (although press reports say that they were retiring from the business!) and had to sell a lot of property in Luddenden and the surrounding valley including the Cornmills. The brothers moved to Sowerby Bridge where one worked as the Manager of a Wharf and the other as a Clerk (1861 census). Hartley Murgatroyd died in 1865 leaving an estate of less than £40. | The brother's seem to have got into some financial difficulties (although press reports say that they were retiring from the business!) and had to sell a lot of property in Luddenden and the surrounding valley including the Cornmills. The brothers moved to Sowerby Bridge where one worked as the Manager of a Wharf and the other as a Clerk (1861 census). Hartley Murgatroyd died in 1865 leaving an estate of less than £40 (roughly £6,000 in today's money). | ||

Twenty-one lots were put up for auction at the Murgatroyd Arms on 19th July 1854. Neither of the Mills sold on the day, but both change hands shortly afterwards. | Twenty-one lots were put up for auction at the Murgatroyd Arms on 19th July 1854. Neither of the Mills sold on the day, but both change hands shortly afterwards. | ||

[[File:1854 auction cover sheet.JPG|thumb|centre|1854 Auction. Original courtesy of John Vaul]] | [[File:1854 auction cover sheet.JPG|thumb|500px|centre|1854 Auction. Original courtesy of John Vaul]] | ||

A full description of the lots going under the hammer was advertised in the [[ | A full description of the lots going under the hammer was advertised in the [[ Newspaper Cuttings#The 1854 Auction listing in the Halifax Courier| Halifax Courier.]] | ||

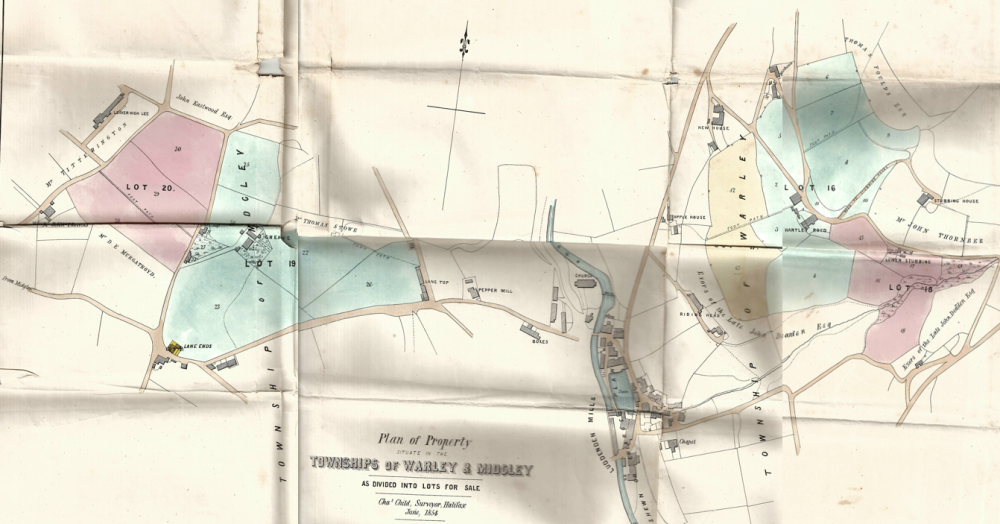

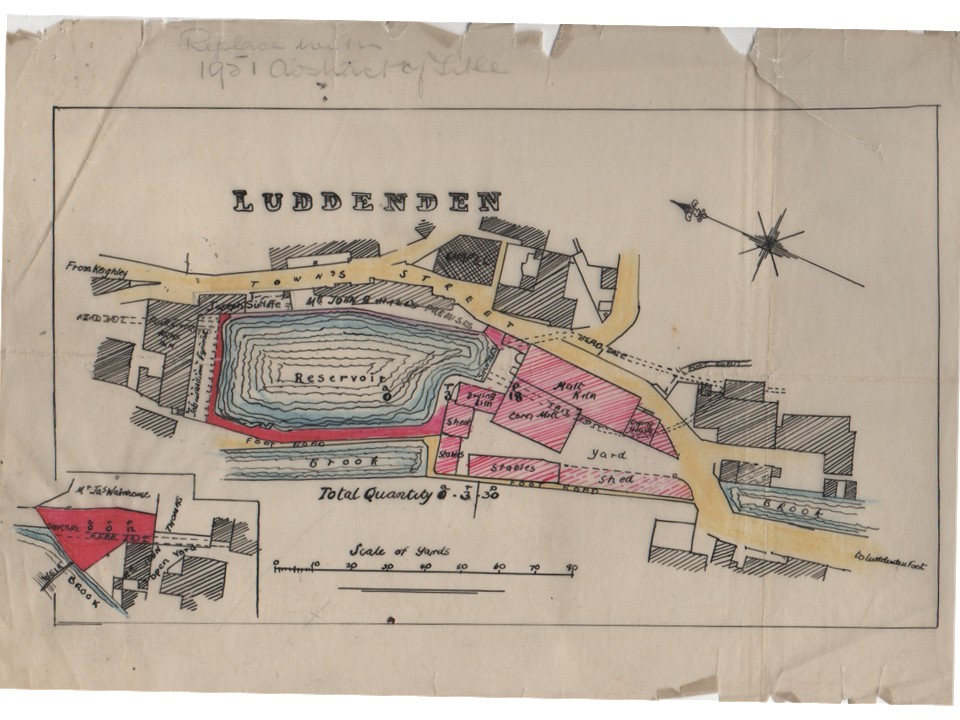

The brochure for the auction included two maps, the first showed the lots for sale on the hills surrounding the village. Lot 21 is not easy to see here but it is the building at Lane ends in Midgley know known as the Old Post Office. In 1854 it was a beer house. | The brochure for the auction included two maps, the first showed the lots for sale on the hills surrounding the village. Lot 21 is not easy to see here but it is the building at Lane ends in Midgley know known as the Old Post Office. In 1854 it was a beer house. | ||

[[File:Auction Brochure map 1.png|centre| | [[File:Auction Brochure map 1.png|centre|1000px|Map showing all 20 auction lots.Original courtesy of John Vaul. Click on image to magnify]] | ||

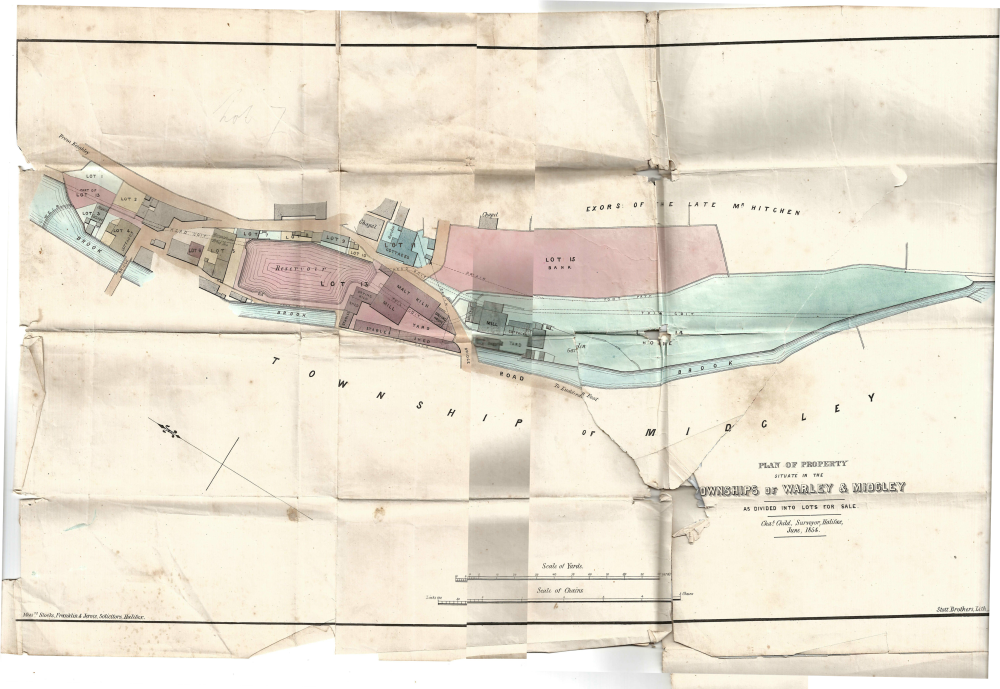

The second map shows the village lots. | The second map shows the village lots. | ||

[[File:Auction Brochure map close up.png|centre|thumb| | [[File:Auction Brochure map close up.png|centre|thumb|1000px| Original courtesy of John Vaul. Click on image to magnify]] | ||

On this second map you can see the details so Lot 13, Upper mill includes the mill pond and a plot of land and sluices next to the weir. The land that the mill occupied is now housing (High Street Court). | On this second map you can see the details so Lot 13, Upper mill includes the mill pond and a plot of land and sluices next to the weir. The land that the mill occupied is now housing (High Street Court). | ||

| Line 81: | Line 124: | ||

''All that valuable Corn Mill called "Upper Mill" situate in Luddenden, with the Malt Kiln, Warehouses, Stabling for 18 Horses, Wagon and Cart sheds, Gighouse, Joiner's Shop, Paved Yards and Outbuildings. Also the Reservoir behind the same, containing 2,008 superficial square yards, with the Water Wheel and the entire Fall of the Luddenden Brook, being about 30 horsepower. And also the Weir and Dam-stones across the Brook, Cloughs, and the Plot of Ground appropriate thereto, together with the use of the head Goit and the Tail Goits.''' | ''All that valuable Corn Mill called "Upper Mill" situate in Luddenden, with the Malt Kiln, Warehouses, Stabling for 18 Horses, Wagon and Cart sheds, Gighouse, Joiner's Shop, Paved Yards and Outbuildings. Also the Reservoir behind the same, containing 2,008 superficial square yards, with the Water Wheel and the entire Fall of the Luddenden Brook, being about 30 horsepower. And also the Weir and Dam-stones across the Brook, Cloughs, and the Plot of Ground appropriate thereto, together with the use of the head Goit and the Tail Goits.''' | ||

'''The Mill is five stories High, and attic, and the whole of the premises have been recently rearranged. The water wheel is a new iron one, 27 feet in diameter and nine on the breast.'' | '''The Mill is five stories High, and attic, and the whole of the premises have been recently rearranged. The water wheel is a new iron one, 27 feet in diameter and nine on the breast.'' | ||

<br> Hang on a minute....did you say 27 feet in diameter? That is some water wheel, the houses on High Street Court are probably about 27 feet high from the ground to the top of their roof. | |||

And just to give you a comparison, there is a huge mill wheel just outside Pateley Bridge at Foster Beck watermill. The wheel here is just a few feet larger (31 foot diameter) but is a bit narrower than the Uppermill Waterwheel. Foster Beck Waterwheel has been preserved, the mill now converted into apartments. | |||

[[File:Foster Beck Waterwheel.jpg|centre|500px|thumb]] <br><br> | |||

<div style="text-align: center;"> '''AND HOW MUCH POWER IS 30 HORSEPOWER?''' | |||

''30 horsepower is 22 kiloWatts.<br>Well that's surprising not very much at all, a small traction engine from 1900 would match this power as would a very very small tractor today, the sort you might use on a small holding.''<br> | |||

''A domestic wind turbine with 2.5 metre blades, the sort you see near farm buildings will generate about 10 kW.'' | |||

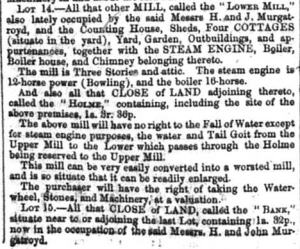

Lot 14 was Lower mill. The three story building now know as The Cornmill is the only surviving part of the mill shown on this map. The two storey part of today's Cornmill was a later addition (but built before 1890. It can be clearly seen on the OS map published in 1894). Again you can see details of the use of the buildings. | '''WHAT WAS THE WHEEL SIZE AT LOWER MILL?'''<br> | ||

''I have yet to find a document describing the last Waterwheel at Lower Mill.<br> The wheel pit survives and this is eleven feet deep. I estimate that the wheel was probably around twenty feet in diameter and around 6 feet wide judging by the wall structure surrounding the wheel pit.<br> We do know that it was replaced with a 12 Horsepower Steam engine, so the wheel would have been less than half as powerful as the Upper Mill Wheel.'' <br><br></div> | |||

Lot 14 was Lower mill. The three story building now know as The Cornmill is the only surviving part of the mill shown on this map. The two storey part of today's Cornmill was a later addition (but built before 1890. It can be clearly seen on the OS map published in 1894). Again you can see details of the use of the buildings on the auction map. | |||

You can see the head and tail goits that fed the water wheel and there is a boiler room and a chimney (so this mill had steam power at this date). There are cottages to the south side of the mill (Earlier documents show that these cottages were originally Oat drying houses, you can't grind wet grain!). [https://www.catalogue.wyjs.org.uk/Record.aspx?src=CalmView.Catalog&id=CC00078%2f31&pos=10]) | You can see the head and tail goits that fed the water wheel and there is a boiler room and a chimney (so this mill had steam power at this date). There are cottages to the south side of the mill (Earlier documents show that these cottages were originally Oat drying houses, you can't grind wet grain!). [https://www.catalogue.wyjs.org.uk/Record.aspx?src=CalmView.Catalog&id=CC00078%2f31&pos=10]) | ||

| Line 96: | Line 153: | ||

The Waterwheel has been replaced by a small Steam engine, (The Uppermill has been fitted with a larger water wheel and there is no longer enough water to power both mills). It is still operating as a Corn Mill but it is recognised that Lower Mill would easily convert into a Worsted Mill and easy to expand. | The Waterwheel has been replaced by a small Steam engine, (The Uppermill has been fitted with a larger water wheel and there is no longer enough water to power both mills). It is still operating as a Corn Mill but it is recognised that Lower Mill would easily convert into a Worsted Mill and easy to expand. | ||

The land of Lot 14 is labelled as 'Holme' and it extends as far as the next weir on the brook. This whole area is now occupied by Blue Bell Walk. The field above Lower Mill, Lot 15 is labelled as 'Bank'. The Eastwood family bought both Lot 14 and 15 in about 1856 and immediately started to convert and extend this mill from a Corn Mill into a sizable woollen mill. | The land of Lot 14 is labelled as 'Holme' and it extends as far as the next weir on the brook. This whole area is now occupied by Blue Bell Walk. The field above Lower Mill, Lot 15 is labelled as 'Bank'. The Eastwood family bought both Lot 14 and 15 in about 1856 and immediately started to convert and extend this mill from a Corn Mill into a sizable woollen mill. A full transcript of this newspaper article can be viewed [[ Newspaper Cuttings#The 1854 Auction listing in the Halifax Courier| here.]] | ||

Below is a hand traced copy of the previous map, highlighting Lot 13. This copy is part of a document drawn up in 1856 when Upper Mill was sold by Hartley and John Murgatroyd to the Thompsons and their partner, Joseph Starkey (who bought a third share in the mill). | Below is a hand traced copy of the previous map, highlighting Lot 13. This copy is part of a document drawn up in 1856 when Upper Mill was sold by Hartley and John Murgatroyd to the Thompsons and their partner, Joseph Starkey (who bought a third share in the mill). | ||

[[File:Detail of Upper Mill.jpg|centre|thumb| | [[File:Detail of Upper Mill.jpg|centre|thumb|1000px|Original courtesy of John Vaul]] | ||

== Upper Mill and The Thompson Family == | == Upper Mill and The Thompson Family == | ||

| Line 106: | Line 163: | ||

In 1856, Upper Mill was Sold to: | In 1856, Upper Mill was Sold to: | ||

* George Thompson | * George Thompson , one third share. | ||

* Joseph Starkey, one third share. | * Joseph Starkey, one third share. | ||

* Robert Thompson (1810-1875), one sixth share. | * Robert Thompson (1810-1875), one sixth share. | ||

* William Henry Thompson (b.1817), one sixth share. | * William Henry Thompson (b.1817), one sixth share. | ||

George Thompson (b.1786) | |||

George, Robert and William Henry Thompson were brothers. | |||

William Thompson (b.1786) was their father and he had an established Corn Milling business based at one of the Mills at Luddendenfoot. There were two mills on Luddenden Brook, one roughly where The Weaver's pub is situated and the other on the opposite bank. One was a woollen Mill, the other a Cornmill but the OS map of the time does not indicate which is which. The Thompson family was living at Middle foot in the 1841 census.<br> | |||

===George Thompson (b.1806)=== | |||

The eldest child, we know little about him. He was single and was living at Denholme in the 1851 census with brother James. Both are listed as Cornmillers. He was living at Bankfield on or near Danny Lane in the 1861 Census by which time he had a third share in the Cornmill at Luddenden and is listed as employing 20 men on the census. By the 1871 census he had retired but was still at Bankfield.<br> | |||

===William Henry Thompson (b.1817)=== | |||

Meanwhile William Henry moves into Cooper House (in 1861 census) and then to Stansfield Hall (on John Naylor Lane, Luddendenfoot). | |||

Having sold his share in Upper Mill, he concentrates his efforts on the family's other Cornmill at Luddendenfoot, Denholme Mill (on the south side of Burnley Road heading towards Cooperfield, it overlooks the canal). | |||

The family had also owned one of the two mills at the bottom of Luddenden Brook as a Cornmill.<br> | |||

Perhaps they needed more space so and moved to Denholme Mill (1854 OS Map: Luddendenfoot mills - one Cornmill, one Woollen mill. Denholme Mills - two Woollen Mills. 1894 OS Map: Luddendenfoot Mills - Two Woollen Mills. Denholme Mills, one Cornmill, one Woollen Mill) | |||

The 1871 census shows that he is employing 16 men and 2 boys. | |||

By 1881 he's employing 30 men and 2 boys and in 1891 he's retired and living in Southport where he spent the rest of his days. | |||

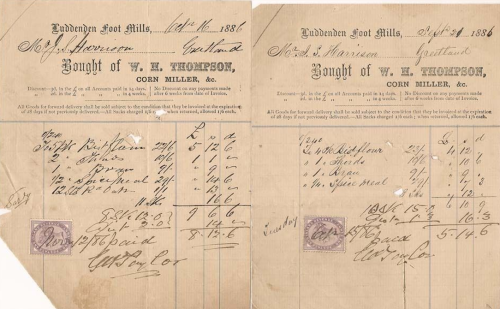

[[File:WH Thompson Invoices with kind Permission of Wayne Ogden.png|centre|500px|thumb| Best flour,Thirds, Bran, Spicemeal and Rolled Oats are on these invoices]] | |||

These invoices remind us that wheat was not the only cereal to be processed in the mill. The staple crop in the Pennines was Oats, not wheat, [[The Cornmill#Wheat, Oats and Barley but no Corn| so what did the Cornmill produce? | |||

]] | |||

===Robert Thompson (1810-1875)=== | ===Robert Thompson (1810-1875)=== | ||

| Line 122: | Line 202: | ||

At this stage Robert is employing 2 men according to the 1861 census. | At this stage Robert is employing 2 men according to the 1861 census. | ||

In 1863, Robert bought William Henry's [https://www.catalogue.wyjs.org.uk/CalmView/Record.aspx?src=CalmView.Catalog&id=CC01688%2f9%2f3&pos=1) Share in the mill] for £1000 | In 1863, Robert bought William Henry's [https://www.catalogue.wyjs.org.uk/CalmView/Record.aspx?src=CalmView.Catalog&id=CC01688%2f9%2f3&pos=1) Share in the mill] for £1000. | ||

By 1871, Robert and his family had moved to Carrfield (which was built for them?) and he is employing 11 men at Upper Mill. | By 1871, Robert and his family had moved to Carrfield (which was built for them?) and he is employing 11 men at Upper Mill. | ||

=== And then things went wrong at Upper Mill..... === | |||

<br> | |||

Robert died in 1875 aged 65, his wife took ownership of the business which their son Arthur ran for her. | Robert died in 1875 aged 65, his wife took ownership of the business which their son Arthur ran for her. | ||

| Line 133: | Line 218: | ||

All of this is recorded on the family memorial in Luddenden Cemetery, the monument, a tall obelisk with a pink granite top is easily located and is situated to the north side of the chapel of rest. | All of this is recorded on the family memorial in Luddenden Cemetery, the monument, a tall obelisk with a pink granite top is easily located and is situated to the north side of the chapel of rest. | ||

This left the family with a big problem as there were no males left to succeed Arthur | This left the family with a big problem as there were no males left to succeed Arthur and no one to run the business. | ||

The | Whether through a fall in demand for milled oats and wheat or through a lack of leadership, the mill ceased to produce flour in the early 1890's and the Thompson heirs rented out sections of Upper Mill to people with new business ventures or for businesses requiring additional space for expansion. The mill in effect became an industrial estate. | ||

On the death of Robert's wife Hannah in 1905 the estate was left to Robert and Hannah's two daughters Mary and Julia, all the male heirs having died. | |||

To add to the family woes, Mary Thompson lost two of her sons in World War One, John Oscar and Albert Louis Thompson. | |||

To be continued... Mary had married her cousin Albert (John William's son) and Julia had married Young Horsefall - he died 1894. | |||

When Mary died in 1931, Julia was the sole heir of Robert's estate. | |||

Julia died in 1946 at which time the remaining estate was sold. | |||

====The Thompson Family - Benefactors of Luddenden==== | ====The Thompson Family - Benefactors of Luddenden==== | ||

| Line 164: | Line 241: | ||

Donating money towards a new road bridge Boy Bridge (1882) across the river Calder at Luddendenfoot (Luddendenfoot Local Board). | Donating money towards a new road bridge Boy Bridge (1882) across the river Calder at Luddendenfoot (Luddendenfoot Local Board). | ||

=The Demise of The Cornmills= | =The Demise of The Cornmills= | ||

| Line 170: | Line 248: | ||

The Cornmills which were originally owned by the Lord of the Manor gradually slipped away from manorial control and new entrepreneurs took them over. | The Cornmills which were originally owned by the Lord of the Manor gradually slipped away from manorial control and new entrepreneurs took them over. | ||

The improvement in the country's infrastructure and the arrival of steam power meant that wheat grown in more fertile soils could be cheaply transported into the Pennines in bulk and once here, no longer needed | The improvement in the country's infrastructure and the arrival of steam power meant that wheat grown in more fertile soils could be cheaply transported into the Pennines in bulk and once here, could be converted into flour using steam power. The local farms were no longer needed to provide oats to feed the ever growing industrial population. | ||

The | The cornmills now needed to be close to canals and railways not close to streams and rivers. And as their output was no longer restrained by the quantity of water available, the mills could be bigger and became more centralised. | ||

The trend continued, pushing the mills to ports like Hull, Liverpool and Manchester (thanks to the ship canal) as imported wheat became readily available. | The trend continued, pushing the mills to ports like Hull, Liverpool and Manchester (thanks to the ship canal) as imported wheat became readily available. | ||

| Line 178: | Line 256: | ||

This regionalisation, with areas of the country being dominant in one particular skill and dependant on other specialist hubs for the items they lacked has grown and now crosses national boundaries to become a global phenomenom! | This regionalisation, with areas of the country being dominant in one particular skill and dependant on other specialist hubs for the items they lacked has grown and now crosses national boundaries to become a global phenomenom! | ||

The Pennine farmers no longer struggled to try and grow | The Pennine farmers no longer struggled to try and grow oats and swapped to struggling to make a living out of cattle farming instead! | ||

The old mills closed and were eventually demolished. A few buildings survived and were converted into apartments!! | The old mills closed and were eventually demolished. A few buildings survived and were converted into apartments!! | ||

| Line 189: | Line 267: | ||

The Eastwood specialised in the manufacture of Woollen Blankets. | The Eastwood specialised in the manufacture of Woollen Blankets. | ||

On acquiring Lower Mill, they leased the building out to another Woollen manufacturer Solomon Priestley and his son John Nicol Priestley (Solomon was originally a butcher in the village, as was his father. Solomon's brother in law was | On acquiring Lower Mill, they leased the building out to another Woollen manufacturer Solomon Priestley and his son John Nicol Priestley (Solomon was originally a butcher in the village and ran the abattoir, as was his father. Solomon's brother in law was James Clay who owned Delph Mill at Luddendenfoot. The two men were business partners in the 1870's). | ||

By 1867, | By 1867, the Eastwoods' had demolished the cottages originally used for drying oats to the south of Lower Mill and built a second shed. They installed a second steam engine to power this new shed. | ||

They, like all the other Mills in the valley, built a small | They, like all the other Mills in the valley, built a small town gas plant (making gas from coal) presumably to provide lighting to the sheds and to enable multi shift working. A small gasometer can be seen on the 1894 OS map roughly in the same position as the current electrical substation. | ||

In 1873 they remortgaged all of the properties they bought from the Murgatroyds, plus their other mills and their home to raise £10,000. This would have been a substantial sum and equivalent to approximately £1 million today. | In 1873 they remortgaged all of the properties they bought from the Murgatroyds, plus their other mills and their home to raise £10,000. This would have been a substantial sum and equivalent to approximately £1 million today. | ||

| Line 206: | Line 284: | ||

Saw Mills<br> | Saw Mills<br> | ||

Warehousing<br> | Warehousing<br> | ||

Albert Yates & Co tool makers<br> | |||

Binns Gas & Oil Engine Co. <br> | |||

==C. Lindley & Co.== | |||

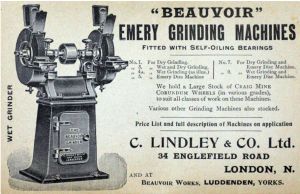

C. Lindley & Co was established in 1865. They expanded and moved into Upper Mill in the late 1890's. | |||

It was Lindley's that introduced the name BEAUVOIR WORKS to the mills. The BEAUVOIR was one of their popular machine tools as shown in this advertisement from 1913. | |||

[[File:Beauvoir grinding machine.jpg|centre|thumb]] | |||

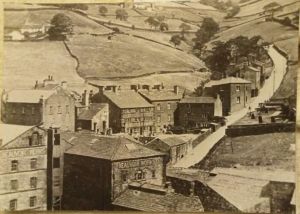

The name Beauvoir Works was painted onto the side of Upper Mill. | |||

[[File:FB IMG 1704557301753.jpg|centre|thumb]] | |||

Work in Progress..... | |||

==New Life in Lower Mill== | ==New Life in Lower Mill== | ||

Dickinson Brothers in Lower Mill - Tailoring <br> | Dickinson Brothers in Lower Mill - Tailoring <br> | ||

Work In progress..... | |||

Latest revision as of 14:32, 2 December 2025

INTRODUCTION

The buildings known today as The Cornmill are the last surviving parts of Luddenden's two historic Cornmills.

The Luddenden Cornmills were owned on and off by The Murgatroyd family since the first recorded mill in 1274. There is a lot of published information about the early history of the mills (including Luddenden Mills). So this article will concentrate on the post-Murgatroyd days, that is from 1854 onwards. But here's a brief early history for you:

A BRIEF HISTORY OF THE WARLEY SOKE MILL

The Mill gets it's first mention in 1274 in The Wakefield Manorial Rolls.

The Cornmill was a Soke Mill and was owned and run by the Lord of the Manor or one of his appointees. All the inhabitants of the Borough had to grind their cereals at their Soke Mill and pay a tax, known as Mulcture, to the Lord of the Manor for this privilege.

Midgley's Soke Mill was on the north bank of the Calder at Brierley bridge by the side of the weir.

And the one for Sowerby was on the Calder's south bank opposite Holmes Park at Luddendenfoot.

The site of the original Warley Soke Mill was a few hundred yards further down the river from today's Mill, somewhere below Lane House and Kershaw House.

It's position is shown on Christopher Saxton's map of 1599 (a copy of which is held by West Yorkshire Archive Service at Halifax Library), but by 1599 the 'new' Mill had been built.

The 'new' mill (the Quenes Milne on Saxton's Map, later to be known as Upper Mill) is clearly marked and was on the site now occupied by High Street Court.

Luddenden at this time was a collection of twelve Houses, the church and the Cornmill.

By 1633 New Mill was getting a bit tired and shabby and in need of an upgrade. The state of the mill was causing a lot of complaints from the locals, as were the state of the access roads to the mills!

So Henry and Jane Murgatroyd had to put their hands in their pockets and pay for some improvements! Their interventions were recorded on this stone lintel which bears their initials and the date of the renovation. This lintel is on display above the mill Stone at the junction of Halifax Lane and High Street in Luddenden.

We get the first mention of Lower Mill in a document from 1738 (West Yorkshire Archive Service: Document Ref Misc 78) with a reference to the cottages at the south end of Lower Mill:

‘wherein oates have and now are dryed and made ready to grind…. Now converted into two dwelling houses’

please note that only Oats are mentioned, not wheat!

The cottages were demolished in the 1860's when the Eastwood family built another 3 storey building of a similar size to the surviving Cornmill building but perpendicular to it. This was situated on the land now occupied by the house know as Jack's Cottage on Bluebell Walk.

This document also mentions that there are:

'three water Corn Mills under one roof called Warley Mills'.

Where the third water wheel was situated is unknown.

The surviving Cornmill buildings are again rebuilds of older buildings, the current buildings are thought to be from the early 1800's for the three storey section with the two storey section next to the 'steps to nowhere' being built around 1860-70. The steps originally gave access to the mill and had a twin on the opposite side of the road to allow easy access between the two mills.

As I mentioned above, the mills had a total of three water wheels in operation for many years, but as wheel technology improved, two large waterwheels with metal spokes were installed to replace the smaller and heavier wooden wheels. In the 1840's Lower Mill was converted to Steam power to allow all the water to be used by one gigantic wheel at Upper Mill.

Upper Mill was sold in the 1850's to the Thompson family who continued to mill grain here until the 1890's. Their milling interests then focussed on their other mill at Denholme Mill on Burnley Road and new tenants were sought for the buildings here in the village.

Lower Mill was also sold in the 1850's.The Eastwood family, who already owned mills in the valley converted it into a Woollen Mill. The Eastwood's were bankrupted shortly afterwards and the building changed hands again, being bought by the Thompson family. They rented it out as a woollen Mill and later (1910-20's) it became a garment sewing shop, run by Dickinson Brothers of Hebden Bridge. Finally it became part of Lindley's Nut & Bolt Factory.

Lindley's started their business in Upper Mill in the late 1890's and gradually expanded across the road to Lower Mill and finally onto the plot of land by the river which was known as The Holme.

The site became derelict when Lindley's shut. In the 1990's, the site was transformed into the housing estate, Blue Bell Walk.

The remaining part of the original Lower Mill was converted into eight residential flats.

Upper Mill was demolished in the 1970's and the houses of High Street Court were built here in the 1990's.

Water Power in Luddenden Dean

Grinding Corn was the earliest record for the use of water power in the Luddenden Valley, but there were many uses for this valuable resource. The valley had at least eleven water mills with a range of uses.

Wheat, Oats and Barley but no Corn

The Cornmill didn't actually grind Corn, well not Corn as we know it today. The word Corn is now used mainly to describe Maize, but historically Corn referred to all Cereal crops.

Here in the Pennines, the main cereal crop would have been Oats. Today when we think of Oats, we think of Scotland!.

Oats grow better than wheat in our cooler, wetter climate and heavy Pennine soil.

The locals tried long and hard to improve the quality of the soil here, bringing lime produced in the Yorkshire Dales and in Lancashire into the valley by packhorse. This was spread over the fields to help break up the clay soil.

The names of pack horse routes across the moors reflect this trade, Limer's Gate for example is a track that runs across Midgley Moor over the summit of High Brown Knoll and down into Luddenden Dean.

Oats were used to make a flatbread know locally as Havercakes (derived the old Norse word for Oats, hafr). Fresh, these resemble a pancake but left to dry, they go hard and once dry, they store well.

Bread made from wheat flour would have been too expensive for the majority of people.

Stew and Hard was a local delicacy, the 'stew' being a slice of cold gelatinous cow heal stew as a filling and the 'hard' being a dry Havercake snapped in half and used like a slice of bread on either side of the stew.

Barley Malting

Barley malting was another important job often associated with Cornmills and here in the village, there was a large malting shed on the site of Upper Mill.

Malted barley was used to produce beer.

In the malting process, the grains are repeatedly soaked and dried to force the grain to sprout. As the grain germinates, it turns stored starch into sugar to fuel the plant's growth. The maltster needs the grain to produce lots of sugar, yeast can then convert this into alcohol in the brewing process.

To germinate the grains they are dried between soakings in long heated drying sheds, the grain is spread thinly on the floor and these are raked to turn the grains over and to keep the moisture at an optimum level.

Once at the correct sugar level, the grains are malted (dried at a higher temperature) so that the sprout of the grain dries and falls off.

The malted grain can be heated to different temperatures to give a range of malt colours for different styles of beer.

Today this is done in ovens with a high degree of temperature control (and we have developed a fascination for very pale beers!!).

Originally, it would have been done with coal fires and a low degree of control and the resulting malt always ended up on the dark side so Beers were darker, porters and stouts being the beer of choice. IPA's were only introduced as the malting ovens became more sophisticated.

Most of the local pubs would have brewed their own beer (micro breweries were the norm, the successful ones expanding to become the big names that we know today). We know that both the Lord Nelson and The Murgatroyd Arms had brewhouses.

Having a supply of malted barley just down the road would have been useful, but the second most important ingredient for a good beer is the right quality of water.

So if you wanted to start a pub, you must build it where there is some good spring water!!

THE CORNMILL AFTER 1854

The Last Days of Murgatroyd Control

The last Murgatroyds to run the mills were brothers Hartley (1797-1865) and John (1799-1873). This branch of the Murgatroyds had run the Cornmills for over two centuries.

The brother's seem to have got into some financial difficulties (although press reports say that they were retiring from the business!) and had to sell a lot of property in Luddenden and the surrounding valley including the Cornmills. The brothers moved to Sowerby Bridge where one worked as the Manager of a Wharf and the other as a Clerk (1861 census). Hartley Murgatroyd died in 1865 leaving an estate of less than £40 (roughly £6,000 in today's money).

Twenty-one lots were put up for auction at the Murgatroyd Arms on 19th July 1854. Neither of the Mills sold on the day, but both change hands shortly afterwards.

A full description of the lots going under the hammer was advertised in the Halifax Courier.

The brochure for the auction included two maps, the first showed the lots for sale on the hills surrounding the village. Lot 21 is not easy to see here but it is the building at Lane ends in Midgley know known as the Old Post Office. In 1854 it was a beer house.

The second map shows the village lots.

On this second map you can see the details so Lot 13, Upper mill includes the mill pond and a plot of land and sluices next to the weir. The land that the mill occupied is now housing (High Street Court).

The map shows the function of each of the buildings in the mill. The majority of the mill was being used for malting barley ready for making beer.

An accompanying document also describes the property;

All that valuable Corn Mill called "Upper Mill" situate in Luddenden, with the Malt Kiln, Warehouses, Stabling for 18 Horses, Wagon and Cart sheds, Gighouse, Joiner's Shop, Paved Yards and Outbuildings. Also the Reservoir behind the same, containing 2,008 superficial square yards, with the Water Wheel and the entire Fall of the Luddenden Brook, being about 30 horsepower. And also the Weir and Dam-stones across the Brook, Cloughs, and the Plot of Ground appropriate thereto, together with the use of the head Goit and the Tail Goits.' 'The Mill is five stories High, and attic, and the whole of the premises have been recently rearranged. The water wheel is a new iron one, 27 feet in diameter and nine on the breast.

Hang on a minute....did you say 27 feet in diameter? That is some water wheel, the houses on High Street Court are probably about 27 feet high from the ground to the top of their roof.

And just to give you a comparison, there is a huge mill wheel just outside Pateley Bridge at Foster Beck watermill. The wheel here is just a few feet larger (31 foot diameter) but is a bit narrower than the Uppermill Waterwheel. Foster Beck Waterwheel has been preserved, the mill now converted into apartments.

30 horsepower is 22 kiloWatts.

Well that's surprising not very much at all, a small traction engine from 1900 would match this power as would a very very small tractor today, the sort you might use on a small holding.

A domestic wind turbine with 2.5 metre blades, the sort you see near farm buildings will generate about 10 kW.

WHAT WAS THE WHEEL SIZE AT LOWER MILL?

The wheel pit survives and this is eleven feet deep. I estimate that the wheel was probably around twenty feet in diameter and around 6 feet wide judging by the wall structure surrounding the wheel pit.

We do know that it was replaced with a 12 Horsepower Steam engine, so the wheel would have been less than half as powerful as the Upper Mill Wheel.

Lot 14 was Lower mill. The three story building now know as The Cornmill is the only surviving part of the mill shown on this map. The two storey part of today's Cornmill was a later addition (but built before 1890. It can be clearly seen on the OS map published in 1894). Again you can see details of the use of the buildings on the auction map.

You can see the head and tail goits that fed the water wheel and there is a boiler room and a chimney (so this mill had steam power at this date). There are cottages to the south side of the mill (Earlier documents show that these cottages were originally Oat drying houses, you can't grind wet grain!). [1])

'wherein Oates have and now are dryed and made ready to grind.... now converted into two dwelling houses or cottages on the south side of the Milne

and there is a building labelled 'Counting House' (probably a place to settle your bill or to pay your mulcture tax) adjacent to the bridge.

Some of the writing on the map is not clear on the scanned copy displayed in this document, but it is clearly readable on the original.

And here is the description of this plot from The Halifax Courier (Saturday 8th July 1854).

The Waterwheel has been replaced by a small Steam engine, (The Uppermill has been fitted with a larger water wheel and there is no longer enough water to power both mills). It is still operating as a Corn Mill but it is recognised that Lower Mill would easily convert into a Worsted Mill and easy to expand.

The land of Lot 14 is labelled as 'Holme' and it extends as far as the next weir on the brook. This whole area is now occupied by Blue Bell Walk. The field above Lower Mill, Lot 15 is labelled as 'Bank'. The Eastwood family bought both Lot 14 and 15 in about 1856 and immediately started to convert and extend this mill from a Corn Mill into a sizable woollen mill. A full transcript of this newspaper article can be viewed here.

Below is a hand traced copy of the previous map, highlighting Lot 13. This copy is part of a document drawn up in 1856 when Upper Mill was sold by Hartley and John Murgatroyd to the Thompsons and their partner, Joseph Starkey (who bought a third share in the mill).

Upper Mill and The Thompson Family

In 1856, Upper Mill was Sold to:

- George Thompson , one third share.

- Joseph Starkey, one third share.

- Robert Thompson (1810-1875), one sixth share.

- William Henry Thompson (b.1817), one sixth share.

George, Robert and William Henry Thompson were brothers.

William Thompson (b.1786) was their father and he had an established Corn Milling business based at one of the Mills at Luddendenfoot. There were two mills on Luddenden Brook, one roughly where The Weaver's pub is situated and the other on the opposite bank. One was a woollen Mill, the other a Cornmill but the OS map of the time does not indicate which is which. The Thompson family was living at Middle foot in the 1841 census.

George Thompson (b.1806)

The eldest child, we know little about him. He was single and was living at Denholme in the 1851 census with brother James. Both are listed as Cornmillers. He was living at Bankfield on or near Danny Lane in the 1861 Census by which time he had a third share in the Cornmill at Luddenden and is listed as employing 20 men on the census. By the 1871 census he had retired but was still at Bankfield.

William Henry Thompson (b.1817)

Meanwhile William Henry moves into Cooper House (in 1861 census) and then to Stansfield Hall (on John Naylor Lane, Luddendenfoot).

Having sold his share in Upper Mill, he concentrates his efforts on the family's other Cornmill at Luddendenfoot, Denholme Mill (on the south side of Burnley Road heading towards Cooperfield, it overlooks the canal).

The family had also owned one of the two mills at the bottom of Luddenden Brook as a Cornmill.

Perhaps they needed more space so and moved to Denholme Mill (1854 OS Map: Luddendenfoot mills - one Cornmill, one Woollen mill. Denholme Mills - two Woollen Mills. 1894 OS Map: Luddendenfoot Mills - Two Woollen Mills. Denholme Mills, one Cornmill, one Woollen Mill)

The 1871 census shows that he is employing 16 men and 2 boys. By 1881 he's employing 30 men and 2 boys and in 1891 he's retired and living in Southport where he spent the rest of his days.

These invoices remind us that wheat was not the only cereal to be processed in the mill. The staple crop in the Pennines was Oats, not wheat, so what did the Cornmill produce?

Robert Thompson (1810-1875)

Robert Thompson was baptised at a Methodist Chapel in Luddenden on 13th August 1810. He was living at Upper Foot (this is the area around Burnley Road heading towards Brierley) in 1851 working as a Corn Miller. After the purchase of Upper Mill, Robert and his family moved into Chapel House, the house that John Murgatroyd had lived in (but the location of this house is unclear - it might actually be the chapel itself).

At this stage Robert is employing 2 men according to the 1861 census.

In 1863, Robert bought William Henry's Share in the mill for £1000.

By 1871, Robert and his family had moved to Carrfield (which was built for them?) and he is employing 11 men at Upper Mill.

And then things went wrong at Upper Mill.....

Robert died in 1875 aged 65, his wife took ownership of the business which their son Arthur ran for her. The business continues to grow and in 1881 it employed 22 men and 2 boys.

But then, the family suffers some set backs, both of Robert and Hannah's sons died. George died in 1882 and Arthur the older son died in 1899. George's only son Frederick William died in 1894.

All of this is recorded on the family memorial in Luddenden Cemetery, the monument, a tall obelisk with a pink granite top is easily located and is situated to the north side of the chapel of rest.

This left the family with a big problem as there were no males left to succeed Arthur and no one to run the business.

Whether through a fall in demand for milled oats and wheat or through a lack of leadership, the mill ceased to produce flour in the early 1890's and the Thompson heirs rented out sections of Upper Mill to people with new business ventures or for businesses requiring additional space for expansion. The mill in effect became an industrial estate. On the death of Robert's wife Hannah in 1905 the estate was left to Robert and Hannah's two daughters Mary and Julia, all the male heirs having died. To add to the family woes, Mary Thompson lost two of her sons in World War One, John Oscar and Albert Louis Thompson.

To be continued... Mary had married her cousin Albert (John William's son) and Julia had married Young Horsefall - he died 1894.

When Mary died in 1931, Julia was the sole heir of Robert's estate. Julia died in 1946 at which time the remaining estate was sold.

The Thompson Family - Benefactors of Luddenden

To be completed

Luddendenfoot Methodist Chapel 1832.

United Methodist Free Church on Halifax Lane in 1837.

Luddendenfoot Congregational Savings Bank.

Donating land for the site of the Infant School on the corner of High Street and New Road.

Donating money towards a new road bridge Boy Bridge (1882) across the river Calder at Luddendenfoot (Luddendenfoot Local Board).

The Demise of The Cornmills

Industrialisation brought people to the valley, more than the local farmers could feed.

The Cornmills which were originally owned by the Lord of the Manor gradually slipped away from manorial control and new entrepreneurs took them over.

The improvement in the country's infrastructure and the arrival of steam power meant that wheat grown in more fertile soils could be cheaply transported into the Pennines in bulk and once here, could be converted into flour using steam power. The local farms were no longer needed to provide oats to feed the ever growing industrial population.

The cornmills now needed to be close to canals and railways not close to streams and rivers. And as their output was no longer restrained by the quantity of water available, the mills could be bigger and became more centralised.

The trend continued, pushing the mills to ports like Hull, Liverpool and Manchester (thanks to the ship canal) as imported wheat became readily available.

This regionalisation, with areas of the country being dominant in one particular skill and dependant on other specialist hubs for the items they lacked has grown and now crosses national boundaries to become a global phenomenom!

The Pennine farmers no longer struggled to try and grow oats and swapped to struggling to make a living out of cattle farming instead!

The old mills closed and were eventually demolished. A few buildings survived and were converted into apartments!!

Lower Mill and The Eastwood Family

The Eastwoods were another of the mill owning families in the Luddenden Dean. They lived at Mill House on Railes Lane. The family were originally farmers. The brothers David, Eli Ogden, Henry, Samuel and Thomas owned Pepper Mill on Duke Street and also Peel House Mill for some of it's life.

They picked up quiet a lot of the property auctioned by Hartley and John Murgatroyd in 1854.

The Eastwood specialised in the manufacture of Woollen Blankets.

On acquiring Lower Mill, they leased the building out to another Woollen manufacturer Solomon Priestley and his son John Nicol Priestley (Solomon was originally a butcher in the village and ran the abattoir, as was his father. Solomon's brother in law was James Clay who owned Delph Mill at Luddendenfoot. The two men were business partners in the 1870's).

By 1867, the Eastwoods' had demolished the cottages originally used for drying oats to the south of Lower Mill and built a second shed. They installed a second steam engine to power this new shed.

They, like all the other Mills in the valley, built a small town gas plant (making gas from coal) presumably to provide lighting to the sheds and to enable multi shift working. A small gasometer can be seen on the 1894 OS map roughly in the same position as the current electrical substation.

In 1873 they remortgaged all of the properties they bought from the Murgatroyds, plus their other mills and their home to raise £10,000. This would have been a substantial sum and equivalent to approximately £1 million today.

The OS map for 1894 shows that the footprint for the buildings at Lower Mill had more than doubled. One of these building can be seen in early photos of the mill, a second three storey building of a similar size to the one that has survived and presumably the one built by the Eastwoods in the 1860's.

Their success did not last for long and the Eastwoods were bankrupted in 1879.

New Life in Upper Mill

WORK IN PROGRESS

A Section on Industrial rejuvenation 1890 to 1910

Saw Mills

Warehousing

Albert Yates & Co tool makers

Binns Gas & Oil Engine Co.

C. Lindley & Co.

C. Lindley & Co was established in 1865. They expanded and moved into Upper Mill in the late 1890's.

It was Lindley's that introduced the name BEAUVOIR WORKS to the mills. The BEAUVOIR was one of their popular machine tools as shown in this advertisement from 1913.

The name Beauvoir Works was painted onto the side of Upper Mill.

Work in Progress.....

New Life in Lower Mill

Dickinson Brothers in Lower Mill - Tailoring

Work In progress.....